Description

Features

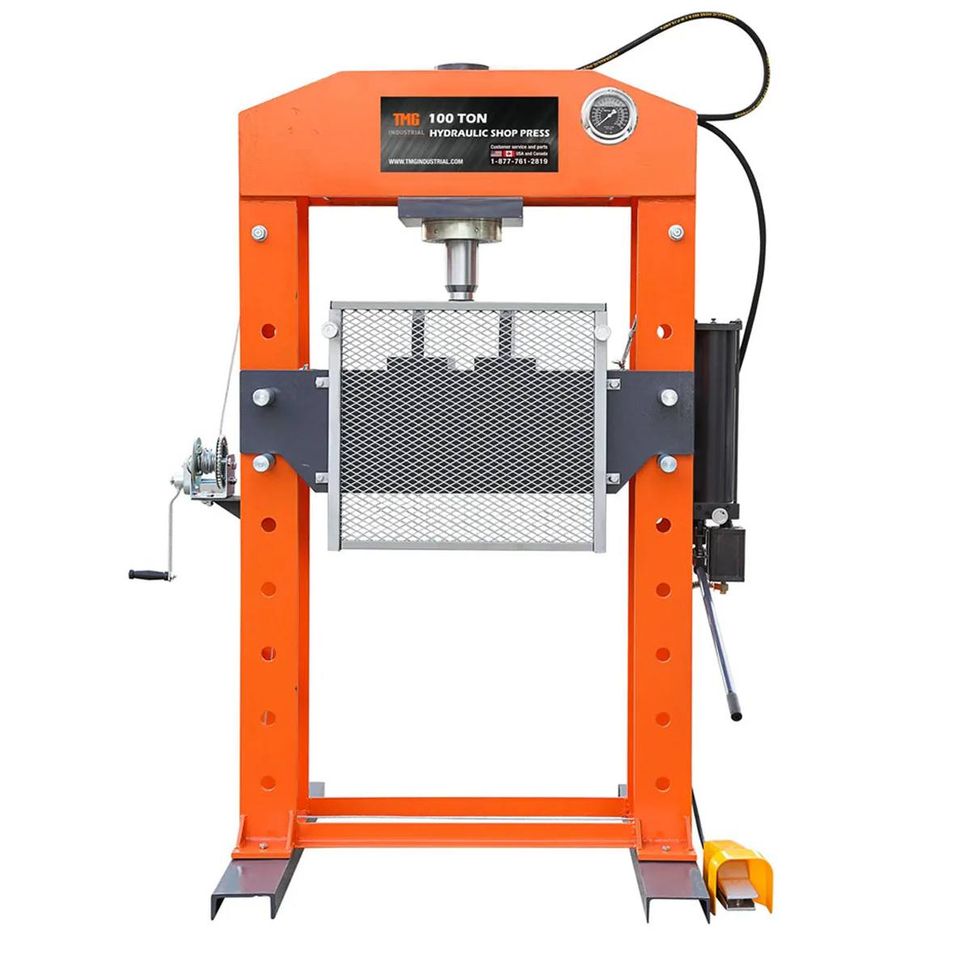

100 ton pressing capacity can be used for stamp work, flattening/bending metal, removing gears/bushings/bearings and more A dual hydraulic cylinder works pneumatically (125 PSI) and manually so you have total control, steady ram speed and smooth overall workflow Heavily constructed and fully welded H-frame adds rigidity and durability for long lasting commercial use in any shop environment Oil filled gauge that is readable in US and metric tons allows you to monitor pressing force accurately and with consistency while operating Steel cable crank winch with non-slip safety clutch provides ergonomic relief by eliminating excessive bending and allowing for easy up/down press bed adjustment Made to handle tough jobs under high pressures; equipped with an overload press valve that prevents use beyond the machine’s capacity Seven height positions provide superior workpiece adaptability to your unique needs and twin springs assist in efficient retraction of the piston rod

Specifications

Assembled size: 59” (L) x 40” (W) x 79” (H)

Pressing force capacity: 100 ton

Air pressure: 110-125 PSI

Cylinder bore: 5”

Ram stroke: 11”

Side stroke: 9″ each side

Bed depth: 11-¾”

Bed width: 32”

Upright opening: 43-½”

Oil filled pressure gauge: 4”

Protective grid guard

Pressing V-block included